3D scanning and reverse engineering

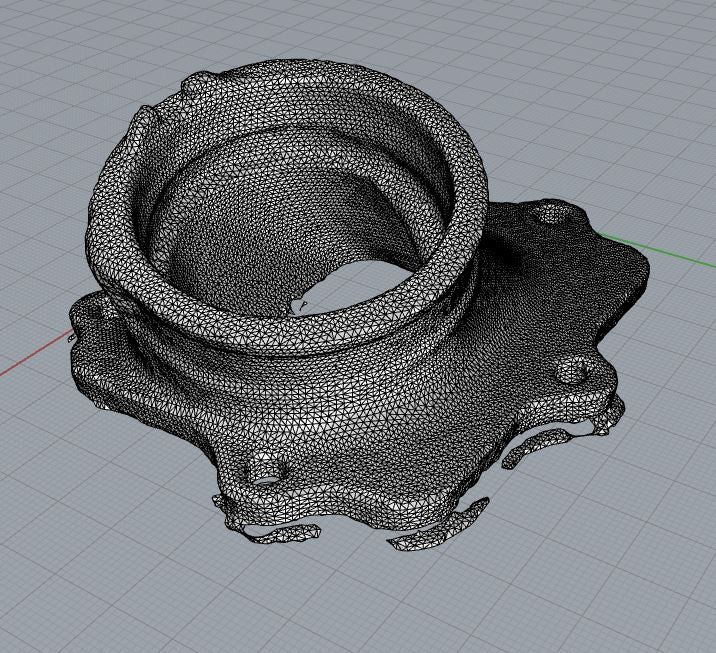

We acquire each component in high precision thanks to our industrial 3D scanner. We can recreate accurate digital models for remakes, adaptations or technical modifications, even in the absence of original drawings.

Below are some of the jobs we have done!

MOVE CLAMP

case study - NEW COMPONENT DEVELOPMENT

-

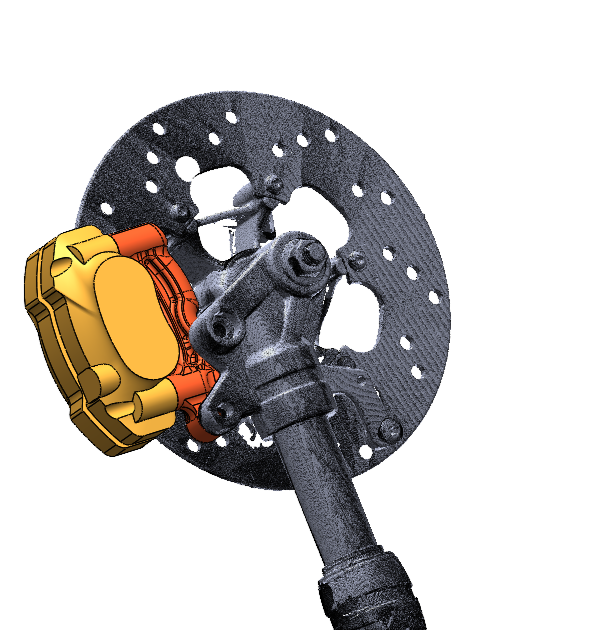

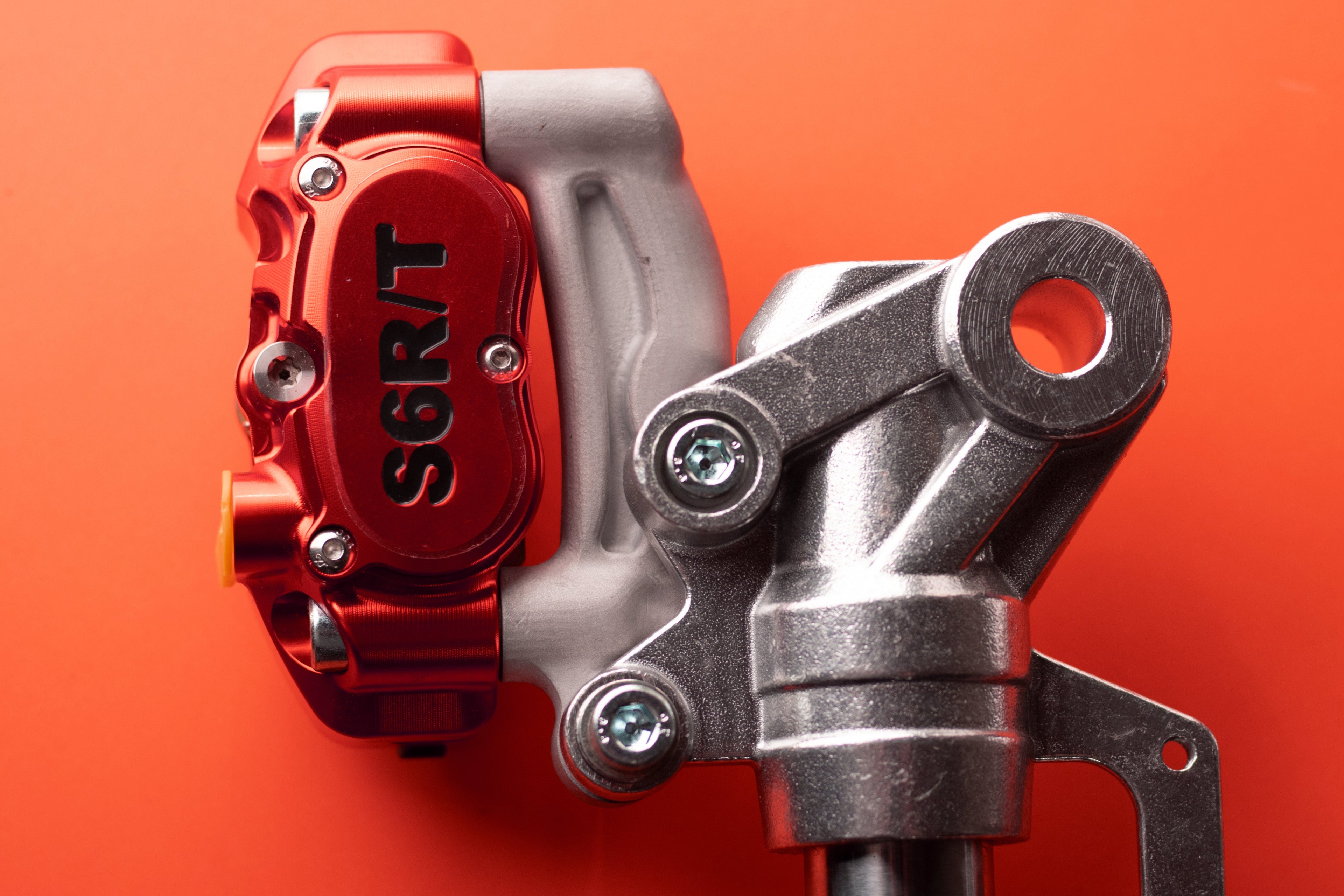

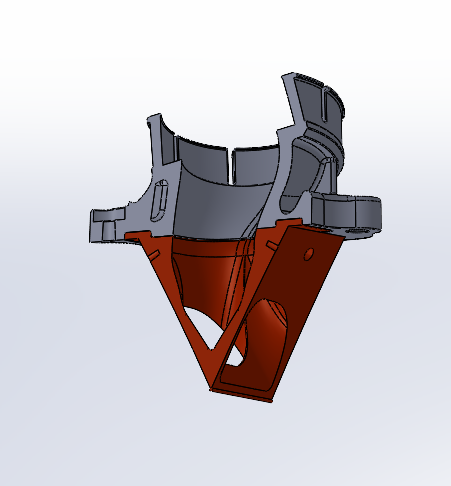

The customer asked us to develop a caliper mover to allow optimal assembly between the radial caliper and the original fork prepared for a completely different caliper.

We scanned the brake caliper, applying a reverse engineering process to recreate a three-dimensional model.

-

In this way, we were able to precisely determine the volumes, slots and centre distances, essential elements for perfectly integrating the caliper with the braking system.

-

Once the project was completed, the gripper shifter was produced using 3D printing technology in aluminum. This process allowed for precise and rapid production, while providing the strength and lightness needed for the specific application.

SUCTION KIT

case study - REVISITATION OF EXISTING COMPONENT

-

Thanks to 3D scanning, we can obtain a precise and personalized replica, avoiding such problems.

Our experience allows us to redesign the intake duct of the manifold and the reed valve pack in order to optimize the air flow, a fundamental aspect for improving engine performance.

-

-

These prototypes are tested on a test bench, where we can measure the actual flow improvement and verify the engine response.

This verification process is crucial to ensure that each component meets the parameters required for effective performance on the track.

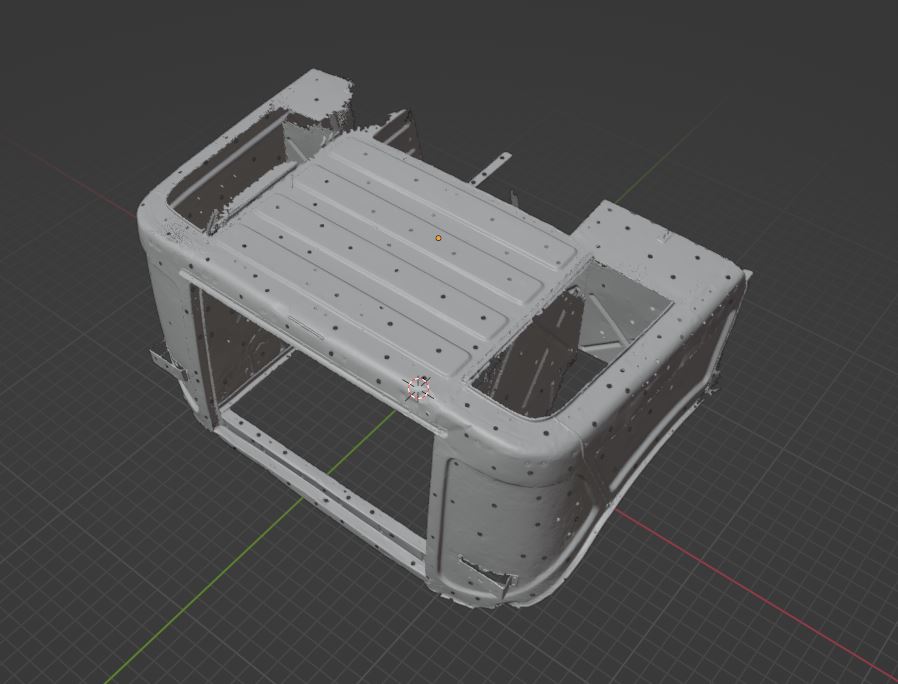

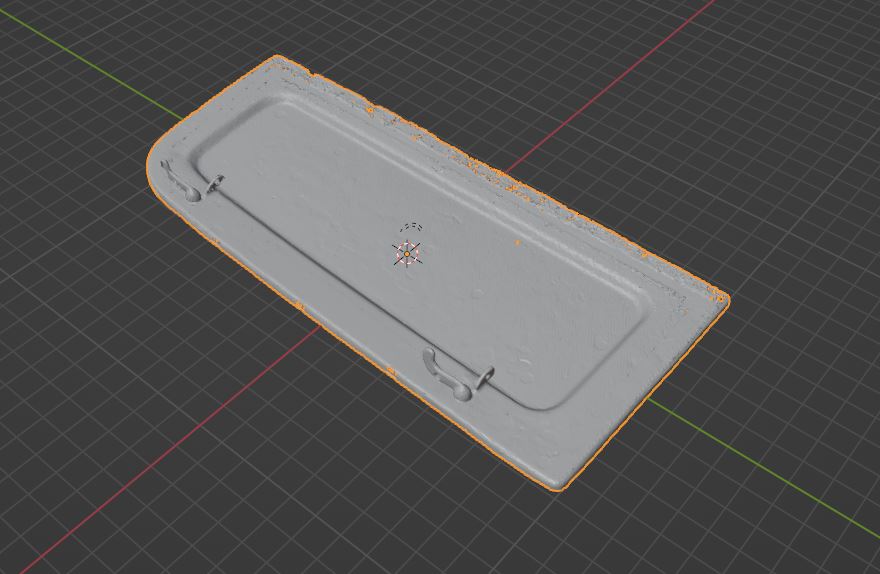

FIAT TM 40

case study - sheet metal reproduction

-

The client wanted to replicate the bodywork of a TM 40 vehicle, a vintage off-road vehicle dating back to the First World War.

Before our intervention, the customer had attempted to make the hull replica using manual measurements. -

This approach proved ineffective: the attachment holes between the fairings and the original frame did not match, preventing correct assembly and causing significant waste of time and resources.

Thanks to our advanced scanning technology, we have captured all the details of the component's external dimensions with high precision.

-

Subsequently, the STL data obtained from the scan were carefully processed and optimized, in order to ensure a fluid and correctly positioned geometry in space, respecting the original dimensions and proportions.

This allowed us to provide the customer with a highly precise model, ready for the production of the matrices necessary for the creation of the hulls.

FCSOLUTION s.a.s

Expansion muffler scan

Condividi